Abstract

Titanium metal is produced commercially by the costly and energy-intensive Kroll process, which is highly matured and optimized. In the last several decades, many new methods have been proposed to reduce the production cost of Ti metal and thus widen its applications. These new methods can be categorized into two main groups: thermochemical and electrochemical methods. Even though detailed operations for different processes vary, the various processes in each category share the same principles. This article outlines the differences and the challenges between different processes on the basis of these shared principles, with an emphasis on the developmental processes. Although several of these new processes are at the laboratory or pilot-plant development stage, it is recognized that systematic fundamental research and open scientific exchanges are still sorely needed in this area to improve the new technologies.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Over the past several decades, there has been continuous research and development of new methods and processes to replace the Kroll process, which is the only commercial process for primary Ti metal production today. Although the Kroll process is well known as an effective method for producing pure Ti metal sponge, it is also an energy-intensive, time-consuming, and thus very costly method. The high cost of Ti sponge is one of the main reasons for the limited use of Ti. There has also been a constant demand from the aerospace industry for lower-cost Ti, especially in the most advanced airplane models where the usage of titanium has increased significantly compared to prior models in conjunction with the use of carbon fiber composites. Unfortunately, to date, none of the developmental processes for titanium production have been able to reach or even approach the commercial scale that would be required to displace the Kroll process to any significant amount, despite the fact that some of the processes have demonstrated promising results from pilot-scale production units. The lack of commercial success to date is partially attributable to the economics of scale that must be achieved before a new process can be competitive compared to a matured existing process. It is also partially attributed to the technical issues that have challenged the development of the new processes. The technical challenges include the removal of impurities such as oxygen and other interstitial elements (Cl, N) which must be at extremely low concentrations in the final product in order to meet application requirements. For example, oxygen content in Ti sponge must be lower than 0.2%, which is difficult to achieve in Ti powders, especially when the particle size of the powder is fine. The requirements for low impurity contents are also very stringent. For example, during the Kroll process, a large portion of energy and time are spent on removing Mg and other volatiles, which contribute significantly to the cost. For the new processes that have been proposed over the years, meeting those challenges has not been easy.

In order to understand the technical issues underlying the challenges, this article assesses the potential of different processes for production of Ti at lower cost than that of the Kroll process. It is recognized that there have been a number of reviews on the production of Ti in the last 20 years.1,2,3, – 4 Most of the developmental processes have been covered in those reviews. The objective of this article is to examine both the fundamental chemistry and the basic technical procedures of different processes in order to understand the advantages as well as challenges of developing an alternative to the Kroll process.

The extractive metallurgical processes for making Ti can be classified into two groups: (1) thermochemical processes and (2) electrochemical processes. The feedstock material can be either purified TiCl4 or TiO2, both of which can be made from natural or synthetic rutile. In the category of thermochemical processes, a number of possible reaction routes are classified based on the Ellingham diagrams for reactions of titanium metal with oxygen and chlorine as shown in Fig. 1a and b.5 The reductants can be selected depending on the type of raw materials. In principle, titanium chlorides can be reduced by Na, Mg, Ca, K, Li, Y, Al, etc., in which Mg and Na metals are the most widely used since they are less expensive to use than other reductants. Whereas titanium oxides can be reduced by Mg, Ca, Y, Al, etc., with Ca metal as the most popular candidate, due to its extra strong reducing ability to remove oxygen from titanium and its low solubility in Ti, which is an important factor to consider due to the possibility of forming unwanted alloys such as when Al is used.

In the category of electrochemical methods, there are also quite a number of processes that have been under development. In principle, the electrochemical processes to produce Ti metal can be classified based on the electrochemical behavior of titanium. In some cases, Ti-bearing raw material is used as the cathode, and, in some other cases, Ti-bearing material is used as the anode. In other cases, the Ti-bearing material is dissolved into the electrolyte, and the dissolved titanium ions pass through the electrolyte and are reduced at the cathode.

Based on the classifications described above, this article discusses typical processes representing each specific reaction route to present a comprehensive view of the opportunities and challenges.

Thermal Reduction of TiCl4

The main precursor for the production of Ti metal is titanium tetrachloride (TiCl4). One advantage of using TiCl4 is that it is relatively easy to remove undesired impurities from TiCl4 during the gaseous purification process, enabling the production of highly purified Ti metal. Another reason is that titanium has a strong affinity to oxygen, resulting in the difficulty of removing oxygen from titanium by most reductants. Thus, the use of TiCl4 has the advantage with respect to controlling both metallic and interstitial impurity contents in Ti primary metal.

The purified TiCl4 is produced by chlorination of enriched Ti slag (impure titanium dioxide) and purification of the crude TiCl4. The reaction equation for reducing TiCl4 by Mg (or Na) is 2 Mg/4Na + TiCl4 → 2MgCl2/4NaCl + Ti. The byproducts of MgCl2 (or NaCl) can be separated from the Ti metal by distillation (or washing). In particular, the processes based on this reaction are the Kroll process8 and the Hunter process,9 respectively. The Kroll, Hunter, and a few other processes aimed at improving them, are briefly discussed in the following sections.

The Kroll Process

In the Kroll process,8 , 10 the purified TiCl4 is reduced by reacting it with liquid Mg metal at around 800–850°C. The reduction products containing Ti metal, by-product MgCl2, residual Mg metal, and a small amount of TiCl3 and TiCl2, are refined by vacuum fractional distillation (0.1–1 Pa) at a high temperature of 1000°C for days to ensure removal of these non-Ti components from Ti metal, which is typically in the form of a sponge.10 This distillation is energy intensive with low thermal efficiency.11 A long period of cooling time is also needed after distillation. To date, the largest facilities can produce 10 tons of Ti metal per reaction chamber; however, the entire cycle takes more than 10 days.11 After more than half a century of optimization, the Kroll process has been developed into a complicated yet highly optimized process.

The Hunter Process

The Hunter process,9 similar to the Kroll process, was commercialized during the middle of the twentieth century, and it was one of the two main commercial processes for production of Ti. However, commercial production of Ti sponge using the Hunter process has gradually come to a halt over the years because the Hunter process is not as economically competitive as the Kroll process for various technical reasons.

During the Hunter process, TiCl4 and Na are placed in a reactor, either simultaneously or TiCl4 is fed gradually into the reactor where Na is already preloaded. The process temperature is set at above 800°C, to ensure Na and NaCl are always in their molten state. Ti crystals form at the surface of the molten pool and settle down. After the reaction completes, the mixture of Ti metal and NaCl is removed from the reactor, and the mixture is ground to powder at ambient temperature. The purified Ti metal is further processed by leaching, washing, and drying. It has been known that the oxygen, carbon, and iron contents in Ti metal produced by the Hunter process can be lower than those produced by the Kroll process.10

The ADMA Process

In a more recent development, the ADMA process12 was developed as a modification of the Kroll process to manufacture pure titanium hydride powder. The key of this process is to introduce hydrogen gas into the reactor during each stage of the process including reduction, phase separation, and cooling. Specifically, according to the patent,12 the reduction of TiCl4 is carried out at 830–880°C in a H2-Ar atmosphere with the partial pressure of hydrogen at 0.05–0.1 atm. After the reduction, the H2 gas preheated to 980–1020°C is injected into the reactor, then full thermal-vacuum separation of Ti from Mg and MgCl2 is performed. Later, controlled hydrogenation and simultaneous cooling of the porous titanium down to 600°C or lower is achieved by passing cold H2 gas into the retort. Then, the porous titanium metal can be removed from the reactor, crushed and ground into the required particle sizes. The integration of the reduction and the hydrogenation processes into one process is expected to reduce the cost and energy of producing titanium metal.

Continuous Processes Based on the Reduction of TiCl4 by Mg

In order to reduce cost, several process alternatives have been investigated with the aim to make the Kroll reaction continuous, including the TiRO process developed by CSIRO,13 the vapor-phase reduction process developed by Hansen et al.,14 and the CSIR-Ti process developed by Vuuren et al.15 The TiRO process is carried out in a fluidized bed at strictly controlled temperatures to ensure that the byproduct MgCl2 is still solid. The vapor-phase reduction process collects the products by an electronic precipitator. And the CSIR-Ti process is characterized by separating one reduction step into two using TiCl2 as the intermediate. However, one common challenge for all these processes is that the products are in the form of powder, whereas the particle sizes of the powder are usually too small, which makes the control of the oxygen content difficult.

Continuous Processes Based on the Reduction of TiCl4 by Na

The Armstrong process,16 which garnered considerable attention and investment in the past two decades, is an example of the efforts to develop a continuous process based on the Hunter process. During this process, molten Na is pumped to meet gaseous TiCl4 in the reactor to react continuously. The resulting Ti metal and NaCl are carried out from the reaction zone by the flowing Na. After the unreacted liquid Na is filtered out and the residual Na is distilled from the filtrate, the Ti metal is collected from the solution after washing out the salt. The product is in the form of mini-sponges, characterized by particulates with micro-porosity. According to one publication,17 an example composition of Ti metal produced by the Armstrong process was reported.

The ARC process,18 developed by the Albany Research Center of the US DOE, is an another continuous two-step process based on the reduction of TiCl4 by Na. However, the product of this process was reported as small aggregates with particle sizes around 5 μm, which makes the control of oxygen difficult.

Thermal Reduction of TiO2

As mentioned earlier, the processes based on the reduction of TiO2 for production of Ti metal are alternatives to the reduction of TiCl4. Thermodynamically, TiO2 can be metallothermically reduced by Ca or Mg. The reaction is Mg/Ca + TiO2→MgO/CaO + Ti or Ti-O solid solution. The byproduct of CaO or MgO can be leached out by using acid instead of being distilled out.

However, the removal of oxygen from titanium oxide is not a trivial challenge, which can be understood based on the Ellingham diagram in Fig. 1c.6 , 7 This figure implies that there are limits to which Ca and Mg can reduce the oxygen content in Ti. Specifically, Mg cannot reduce oxygen from titanium oxides and Ti-O solid solutions to less than 0.5 wt.% O. Ca also has a reduction limit at 700°C of no less than 0.02 wt.%. Note that the discussions on the thermodynamic limit assume saturated CaO or MgO, with an activity of 1.0. The oxygen potentials in MgO and CaO can decrease if the activities can be reduced. In this section, several calciothermic processes are described. A recent development of the magnesiothermic reduction process is also presented.

MHR Process

Ca is often used to reduce TiO2 to make Ti metal. Four different forms of Ca, including CaH2, vapor-phase Ca, and liquid Ca, have all been investigated as options for reduction. The MHR process dates back to 1945, and the most notable work was reported by Borok in 196519 and Froes et al. in 1998.20 Calcium hydride was used to reduce TiO2 directly. Although there was reportedly a commercial operation in Russia based on this process, concrete information is not available in the public ___domain.

PRP Process

The preform reduction process (PRP) was developed by Okabe et al.21 In this process, reductant Ca is placed underneath TiO2 without direct contact. TiO2 is pre-fabricated in the form of blocks mixed with a flux of either CaO or CaCl2, and the preform is then reacted with Ca vapor at temperatures between 800 and 1000°C. Fine titanium powder is obtained by leaching the product with acid.22

Molten Salt Facilitated Ca Reduction Process

Suzuki et al.23 reported another method of calciothermic reduction of TiO2 in molten CaCl2. The CaCl2 plays the role of transporting Ca to react with TiO2, and dissolving the CaO by-product. In one of the publications, an oxygen content of 1000 ppm was reported.23

EMR Process

Titanium powder can also be produced through a process called electronically mediated reaction (EMR), using calcium as the reductant.24 Feed material TiO2 and reductant were connected in an otherwise electrically disconnected set-up in a molten calcium chloride salt.21 The reduction of TiO2 proceeds without direct physical contact with the reductant.

Mg-Based Reduction

Parallel to the reduction of TiO2 by Ca, the reduction by Mg metal has also been studied, since Mg metal is less costly and safer to handle than Ca metal. The initial concept of magnesiothermic reduction of TiO2 dates back to 1964, as reported in a US patent.25 Rutile was reduced by Mg granules with the help of MgCl2 flux at 750°C for a long time in a hydrogen atmosphere. After leaching by acid, the Ti metal powder with an oxygen content as low as 1.7 wt.% was obtained. Moreover, a number of other investigations on Mg reduction have been carried out by either mixing Mg with TiO2 or using Mg vapor to reduce TiO2.26,27,28, – 29

Deoxygenation of Ti-O Solid Solutions

As indicated above, the oxygen content in Ti cannot be reduced to be lower than 1 wt.% at approximately 700°C by a simple reduction by Mg. Any attempts to produce Ti metal from TiO2 by a single-step magnesiothermic reduction would be very difficult, if not impossible. Further removal of oxygen, which is called deoxygenation, from the reduction reaction product, i.e. Ti-O solid solutions (expressed as Ti(O)), is thus necessary. In general, the remaining oxygen in Ti-O solid solution can be deoxygenated using Ca.30 Recently, it has been demonstrated that the deoxygenation can also be accomplished using Mg in hydrogen atmosphere.31 Conceptually, the reduction and the deoxygenation can thus be expressed by the following reactions.

-

Reduction: TiO2 + Mg→Ti(O) + MgO;

-

Deoxygenation: Ti(O) + Ca→Ti + CaO, or

-

Ti(O) + Mg + H2→ Ti(H) + MgO

Deoxygenation of Ti or Ti alloys by Ca has been reported in the literature, where liquid Ca, vapor Ca, Ca-saturated salt, and solid Ca were all reported as deoxygenation agents. In one case, a process called the DOSS process32 patented by RMI uses liquid Ca without CaCl2 flux to remove the alloyed oxygen. Similar to the DOSS process, a molten CaCl2 salt-assisted liquid Ca deoxygenation process was reported by operating at 900–950°C in Ar.33 In another case, the deoxygenation was conducted using the chemically activated Ca-saturated salt at 1000–1200°C through dissolving Ca vapor into CaCl2 salt.34 A Ca vapor process was developed to operate in vacuum at relatively low temperatures, in the range of 500–830°C.35 Recently, a low-temperature deoxygenation process has been developed,36 , 37 which operates at moderate temperatures (<800°C) when Ca metal is still in its solid state.

Hydrogen Assisted Magnesiothermic Reduction of TiO2 (HAMR) Process

As mentioned above, deoxygenation of Ti or Ti alloys can be carried out using Mg in the presence of hydrogen at low temperatures (600–800°C).31 The new deoxygenation approach is based on the thermodynamic tuning of the relative stability of MgO versus that of Ti-O solid solutions with the assistance of hydrogen. It was found that hydrogen can destabilize Ti-O by forming Ti-O-H alloy, making it possible to reduce oxygen content in Ti-O solid solution to a very low level by using Mg. In addition to the thermodynamic advantage of using hydrogen, alloying hydrogen is known to be able to make the Ti or Ti alloys more impervious to oxidation in air. It is noted here that the deoxygenation by-product MgO can be leached out by acid. The hydrogen in the Ti or Ti alloy powders can also be readily removed via a thermal dehydrogenation treatment. It has been demonstrated that the oxygen content in Ti or Ti alloys can be reduced to a few hundred ppm.

Based on the thermodynamic principles described above, a new process for producing Ti metal by directly reducing TiO2 with Mg was developed. The process is called hydrogen-assisted magnesiothermic reduction, or HAMR for short.38 There are three key elements for the HAMR process: the use of hydrogen atmosphere, the use of MgCl2-bearing molten salt, and the two-step process to remove oxygen, i.e. reduction and deoxygenation steps. The use of hydrogen is the enabling science that makes it possible to reduce oxgyen in Ti to very low levels. The role of molten MgCl2 salt during the reaction is primarily a kinetic one of helping the transport of reaction species. The two-step approach overcomes practical difficulties to achieve complete reduction. It has been demonstrated38 that Ti metal produced using the HAMR process meets the requirements of industry standards (e.g. ASTM-B299-13) for chemical compositions, including those for interstitial elements.

Electrolysis with Ti-Bearing Materials as the Cathode

The FFC-Cambridge Process

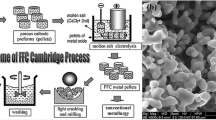

The FFC-Cambridge process, developed by Chen, Fray, and Farthing,39 , 40 is arguably the most well-known example of the electrolytic processes. In this process, the raw material of TiO2 is pressed into pellets and slightly sintered and then used as the cathode, with molten CaCl2 as the electrolyte,41 and graphite as the consumable anode. The reduction of TiO2 during the FFC process is accomplished by the ionization of the oxygen from the titanium-bearing cathode which diffuses to the anode and is discharged.

Since the invention of this approach, there has been considerable work and reporting on the reaction pathway of the reduction of TiO2 to Ti.42,43, – 44 It is believed that the cathode reactions are very complex, as listed in Fig. 2a, and the pathway from TiO2 to TiO is very critical. The anode reaction is the discharge of O2− ions at a carbon-based anode. Obviously, the generation of CO2 gas is preferred over CO and Cl2 gas. The use of graphite anodes still has opportunities for improvement to produce a high-quality product.

Schematic illustration of eletrolytic cell in (a) FFC-Cambridge process (reprinted with permission from Ref. 40), (b) OS process (reprinted with permission from Ref. 48), (c) QIT process (adapted from Ref. 50), (d) when Ti-bearing material is used as the anode (adapted from Refs. 51,52,, 52, and 53), (e) SOM process (reprinted with permission from Ref. 61)

It is estimated that the optimized FFC-Cambridge process is economically promising to produce Ti metal from TiO2 directly with a timeframe of 14–16 h, current efficiency at around 40%, and energy consumption around 17 kWh/kg at 900°C. It is noted here that the FFC process does not remove other elements in the feedstock material, thus the final product will be a reflection of the impurities in the original feed material, and therefore it uses high-purity oxide in order to produce pure Ti metal.

The OS Process

The OS process, proposed by Ono and Suzuki et al.45,46,47,48, – 49 in 2002, is based on a combination of the reduction of TiO2 by Ca and the electrolysis of CaO to regenerate Ca in a molten CaCl2 salt (Fig. 2b). One of the most important underlying principles is that molten CaCl2 is capable of dissolving a few molar percent of Ca and CaO. Since the consumable carbon anode is used here, the reaction at the anode is C + 2O2−→CO2 + 4e, while the reaction at the cathode is Ca2++2e→Ca. However, the reverse reactions of 2Ca + CO2→C + 2CaO and Ca + CO→C + CaO may also take place, and the carbon dust may contaminate the Ti metal and the molten salt. Thus, the cathode design is one key issue of this process.

The QIT Process

The QIT process,50 patented by Francois Cardarelli in 2009, is a method of electrowinning Ti metal from TiO2-containing compounds in the liquid state (Fig. 2c). Specifically, this process uses a molten TiO2-containing compound as the cathode on the bottom. A layer of electrolyte, such as molten salts (e.g. CaF2), or a solid-state ionic conductor (e.g. YSZ or beta Al2O3), is used as the O2− ion transporter in the middle. The anode can be a consumable carbon, or an inert stable anode, or a gas diffusion anode fed with a combustible gas (e.g. H2, CO, etc.). The temperature for electrolysis in this process is between 1700°C and 1900°C. Since this method is designed to be a downstream process to extract Ti from the crude molten titanium slag produced by the electric arc furnace used for the smelting of ilmenite concentrate, the impurity concentrations in the titanium slag, including those of Fe, Mn, Cr, and Si, are likely to be high, and a predeoxidation step may be needed to remove these impurities. The overall reaction with a consumable carbon anode is TiO2(liq.)↓ + C(sol.) → Ti(liq.)↓ + CO2(gas)↑. Some examples in their patent showed that a specific energy consumption lower than 7 kWh/kg Ti was achieved.

Electrolysis with Ti-Bearing Material as the Anode

As another category of electrochemical method for Ti production, several processes (Fig. 2d) including the USTB process,51 the MER process,52 and the Chinuka process53 use Ti-bearing material as the consumable anode, in which titanium is in a low valence state. Iron, molybdenum, stainless steel, and similar metals are often used as the cathode in these processes. Molten salt, which may be selected from the group consisting of LiCl, NaCl, KCl, MgCl2, CaCl2, KF, NaF, LiF, etc., and mixtures thereof, is used as the electrolyte. TiO2 and TiCl4 cannot be used as the consumable anode directly because TiO2 has little or no solubility in molten salt electrolytes. And TiCl4, as a covalent compound, also has limited solubility in fused salt, and does not form complexes with other inorganic salts.52

During this category of electrolytic processes, the anodic dissolution of the Ti-bearing material produces either Ti2+ and/or Ti3+ ions, among which Ti2+ is the more preferred, and the gases, including CO, CO2, N2, are released. Meanwhile, the Ti metal is deposited at the cathode according to the reactions Ti3++3e = Ti0 or Ti3++e = Ti2+ and Ti2++2e = Ti0. Current efficiency can be relatively high for both anode and cathode; however, it can also be relatively low for the cathode if Ti3+ ions are formed during anodic dissolution.

The concept of electrolyzing a TiC-TiO solid solution was proposed in 1955 by Wainer et al.54 They proposed that Ti metal could be produced by electrolysis of a mutual solid solution of TiC and TiO, in which the molar ratio of TiC to TiO does not exceed 1.0. The solid solution was prepared by heating the mixture at a temperature of 2000–2100°C for around 1 h under vacuum or inert atmosphere of argon or helium. The molar ratio of TiC to TiO was controlled to avoid the formation of free carbon particle which would short-circuit the cell and contaminate the Ti metal. Hereafter, the representative processes are described, which are different from each other mainly due to the differences in making the Ti-bearing anode.

The USTB Process

The USTB process, invented by Zhu et al in 2005, uses a solid solution of TiO·mTiC (0 ≤ m ≤ 1)55 and titanium oxycarbonitride (TiC x O y N z , 0 < x ≤ y ≤ 1, 0 < z < 1, x + y + z = 1)51 as the anode. According to the report,55 TiO2 raw material was mixed with TiC or C under a certain stoichiometry to prepare TiO·mTiC, then the mixture was pressed into a bar, and sintered at temperatures in excess of 1000°C under vacuum56 to form the solid solution. Ti2CO is preferred. As for the preparation of TiC x O y N z , the procedure was similar except that the reduction takes place in a N2 atmosphere and TiO0.25C0.25N0.5 was preferred.57

The MER Process

The MER process, patented by Withers and Loutfy52 in 2008, is characterized by using a titanium suboxide/carbon composite as an anode, in which the titanium suboxide can be TiO, Ti2O3, Ti3O5, Ti4O7, and mixtures thereof, prepared by carbothermic reduction of TiO2 or Ti slag. TiO is the most preferred suboxide. In most cases, the suboxide obtained will be mixed with carbon and a binder, pressed, and sintered at 1100–1300°C to obtain a well-bonded strong composite anode.

The Chinuka Process

The Chinuka process, developed by Fray and Jiao in 2010 , 53 aimed to find a new way to use the devalued resources of TiO2 which are too fine or contain too much impurities (for instance, CaO). The Chinuka process uses impure TiO2 to react with TiC53 or carbon58 to prepare a consumable anode made of titanium oxycarbide (Ti2CO). The electrolysis was performed in a molten salt at 570–910°C. According to the patent,53 the impurities in the anode, including Al, Ca, Cr, Fe, and Si, can anodically dissolve into the molten salt with Ti; however, most of them will remain in the electrolyte due to their low concentrations. It is therefore necessary to purify the electrolyte by monitoring the buildup of impurities to ensure the purity of the Ti deposit.

Electrolysis Using Non-Ti-Bearing Material Electrodes

The SOM process,59 , 60 in which Ti-bearing material is not used as the electrodes, was introduced by Uday Pal et al. to solve two main challenges facing electrolysis processes, i.e. ion cycling in multivalent metals and the difficulty of finding a robust inert anode.61 It also has the potential to avoid the generation of CO2/CO.

SOM stands for solid oxide membrane. The SOM method had been used to electrolyze MgO earlier. The configuration of a SOM setup for TiO2 reduction, as shown in Fig. 2e, includes a steel crucible containing MgF2-CaF2-TiO2 flux, an inert metal rod as the cathode, and a yttrium-stabilized-zirconia (YSZ) membrane in the form of a one-end-closed tube containing either a liquid metal as the anode or liquid MgF2-CaF2 flux connecting the YSZ membrane to an anode. The operation temperature for this process ranges from 1150 to 1300°C. During the operation, Ti4+ ions dissolved in the melt will be reduced at the cathode, and the O2− ions will pass through the YSZ membrane and be discharged at the anode. In a modified SOM process, TiO2 is pre-reduced to TiO or even metallic titanium by Mg gas produced by the SOM process, then only Ti2+ cations will form after dissolution in the SOM process, and multiple valence titanium ions will be avoided, thus inhibiting the deposit of titanium suboxides at the cathode.

Concluding Remarks

Even though there are strong interests in the industry for finding a better method to produce Ti metal, and a large number of new concepts and improvements have been investigated at the laboratory or even at pilot plant scales, there is no new process to date that can replace the Kroll process commercially. On the one hand, new processes must be able to produce Ti metal with equivalent or better quality, i.e. purity, than that produced by the Kroll process. In fact, very limited compositional data on the purity of Ti metal prepared by the various methods are available in the open literature except for the Ti metal powder produced by the HAMR process; thus it is difficult to evaluate and compare the pros and cons of different methods. Of course, only when substantial quantities of metal are produced by those different methods will it be possible to judge whether a new process has the potential to replace the Kroll process. On the other hand, high-purity Ti metal must also be produced at significantly lower cost than that by the Kroll process. The quality and cost objectives must be met simultaneously. It is fair to say that a process is not a low-cost process until it can produce the metal at low cost and meet the requirements as defined in ASTM and/or other industry standards.

References

D. Fray, Int. Mater. Rev. 53, 317 (2008).

C.G. McCracken, C. Motchenbacher, and D.P. Barbis, Int. J. Powder Metall. 46, 19 (2010).

F. Froes and D. Eylon, Int. Mater. Rev. 35, 162 (1990).

E. Kraft, Summary of Emerging Titanium Cost Reduction Technologies (Vancouver: EHK Technologies for ORNL, 2004).

T.B. Reed, Free Energy of Formation of Binary Compounds: An Atlas of Charts for High-Temperature Chemical Calculations (Cambridge: The MIT Press, 1972).

J.P. Coughlin, Contributions to the Data on Theoretical Metallurgy. XII. Heats and Free Energies of Formation of Inorganic Oxides (US Bureau of Mines Bull., 542, 1954).

A.D. Mah, K.K. Kelley, N.L. Gellert, E.G. King and C. O’Brien: Thermodynamic properties of titanium-oxygen solutions and compounds (Bureau of Mines, 1955).

W. Kroll, Trans. Electrochem. Soc. 78, 35 (1940).

M.A. Hunter, J. Am. Chem. Soc. 32, 330 (1910).

W. Mo, Titanium Metallurgy (in Chinese) (Beijing: Metallurgical Industry Press, 1998).

S. Seetharaman: Treatise on Process Metallurgy, Volume 3: Industrial Processes. (Newnes: Elsevier, 2013).

S.A. Kasparov, A.G. Klevtsov, A.I. Cheprasov, V.S. Moxson and V.A. Duz, U.S. Patent 8007562 B2, 2011.

C. Doblin, A. Chryss, and A. Monch, Key Eng. Mater. 520, 95 (2012).

D.A. Hansen and S.J. Gerdemann, JOM 50, 56 (1998).

D.S. van Vuuren, S.J. Oosthuizen, and M.D. Heydenrych, J. South Afr. Inst. Min. Metall. 111, 141 (2011).

G. Crowley, Adv. Mater. Process. 161, 25 (2003).

C. Wei, Y. Yamamoto, and W.H. Peter, Key Eng. Mater. 436, 123 (2010).

S.J. Gerdemann, L.L. Oden and J.C. White, in Proc. 1997 Materials Week ‘Titanium Extraction and Processing’, ed. by B. Mishra, G.J. Kipouros (TMS, Indianapolis, IN, 1997), pp. 49–54.

B.A. Borok, Trans. Cent. Res. Inst. Ferrous Metall. 43, 69 (1965).

F.H. Froes, JOM 50 (9), 41 (1998).

T.H. Okabe, T. Oda, and Y. Mitsuda, J. Alloys Compd. 364, 156 (2004).

T.H. Okabe, T. Kakihira and T. Abiko, in Proc. TMS 2004 Symp on ‘Electrochemical Measurements and Processing of Materials’, (TMS, Charlotte, NC, 2004), pp. 67–74.

R.O. Suzuki and S. Inoue, Metall. Mater. Trans. B 34, 277 (2003).

I. Park, T. Abiko, and T.H. Okabe, J. Phys. Chem. Solids 66, 410 (2005).

T.A. Henrie, H. Dolezal, and E.K. Kleespies, U.S. Patent 3,140,170 A, 1964.

R. Bolívar and B. Friedrich, in Proc. EMC 2009, (TMS, Innsbruck, 2009), pp. 1–17.

C. Won, H. Nersisyan, and H. Won, Chem. Eng. J. 157, 270 (2010).

H. Nersisyan, J. Lee, and C. Won, Mater. Res. Bull. 38, 1135 (2003).

M. Eshed, A. Irzh, and A. Gedanken, Inorg. Chem. 48, 7066 (2009).

Y. Zhang, Z.Z. Fang, Y. Xia, Z. Huang, H. Lefler, T.Y. Zhang, P. Sun, M.L. Free, and J. Guo, Chem. Eng. J. 286, 517 (2016).

Y. Zhang, Z.Z. Fang, P. Sun, T.Y. Zhang, Y. Xia, C.S. Zhou, and Z. Huang, J. Am. Chem. Soc. 138, 6916 (2016).

R.L. Fisher, U.S. Patent 4,923,531, 1990.

R.O. Suzuki, A. Saguchi, W. Takahashi, T. Yagura, and K. Ono, Mater. Trans. 42, 2492 (2001).

T. Okabe, T. Oishi, and K. Ono, J. Alloys Compd. 184, 43 (1992).

J.M. Oh, B.K. Lee, C.Y. Suh, S.W. Cho, and J.W. Lim, Mater. Trans. 53, 1075 (2012).

Z. Zak Fang, Y. Xia, P. Sun, and Y. Zhang, Patent Application 62/086,524, 2016.

Y. Xia, Z.Z. Fang, P. Sun, Y. Zhang, T.Y. Zhang, and M. Free, J. Mater. Sci. 52, 4120 (2017).

Y. Zhang, Z.Z. Fang, Y. Xia, P. Sun, B. Van Devener, M. Free, H. Lefler, and S.L. Zheng, Chem. Eng. J. 308, 299 (2017).

D. Fray, T. Farthing, and Z. Chen, U.S. Patent 10/778,529, 2004.

G.Z. Chen, D.J. Fray, and T.W. Farthing, Nature 407, 361 (2000).

G.Z. Chen, in Advances in Powder Metallurgy: Properties, Processing and Application, ed. by I. Chang, Y. Zhao (Woodhead publishing, Cambridge, 2013)

C. Schwandt and D.J. Fray, Electrochim. Acta 51, 66 (2005).

R. Bhagat, D. Dye, S.L. Raghunathan, R.J. Talling, D. Inman, B.K. Jackson, K.K. Rao, and R.J. Dashwood, Acta Mater. 58, 5057 (2010).

D.T.L. Alexander, C. Schwandt, and D.J. Fray, Electrochim. Acta 56, 3286 (2011).

R.O. Suzuki and K. Ono, in Proc. 18th Annual ITA Conf., (International Titanium Associate Orlando, FL, 2002), pp. 1–24.

R.O. Suzuki, K. Ono, and K. Teranuma, Metall. Mater. Trans. B 34, 287 (2003).

R.O. Suzuki and S. Fukui, Mater. Trans. 45, 1665 (2004).

R.O. Suzuki, J. Phys. Chem. Solids 66, 461 (2005).

K. Ono and R. Suzuki, JOM 54, 59 (2002).

F. Gardarelli, U.S. Patent 7,504,017 B2, 2009.

H.M. Zhu, Q.Y. Wang, and S.Q. Jiao, Patent Application CN 201310421132.7, 2013.

J.C. Withers and R.O. Loutfy, U.S. Patent 7410562 B2, 2008.

D.J. Fray and S.Q. Jiao, Patent Application PCT/GB2010/051237, 2010.

E. Wainer, U.S. Patent 2722509, 1955.

S.Q. Jiao, H.M. Zhu, and X.F. Gu, Patent Application CN 200510011684.6, 2005

S.Q. Jiao and H.M. Zhu, J. Alloys Compd. 438, 243 (2007).

Q.Y. Wang, J. Song, J. Wu, S.Q. Jiao, J. Hou, and H.M. Zhu, Phys. Chem. Chem. Phys. 16, 8086 (2014).

D. Jewell, S.Q. Jiao, M. Kurtanjek, and D.J. Fray: Titanium Metal Production via Oxycarbide Electrorefining (International Titanium Association, 2012).

U.B. Pal, JOM 60, 43 (2008).

M. Suput, R. Delucas, S. Pati, G. Ye, U. Pal, and A.C. Powell, Miner. Process. Extr. Metall. Rev. 117, 118 (2008).

U.B. Pal and A.C. Powell, JOM 59, 44 (2007).

Acknowledgements

The authors acknowledge the funding support by the Advanced Research Project Agency for Energy (ARPA-E) of the US DOE (DE-AR0000420) through the Modern Electro/Thermochemical Advances in Light-Metal Systems (METALS) program.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Zhang, Y., Fang, Z.Z., Sun, P. et al. A Perspective on Thermochemical and Electrochemical Processes for Titanium Metal Production. JOM 69, 1861–1868 (2017). https://doi.org/10.1007/s11837-017-2481-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-017-2481-9