Abstract

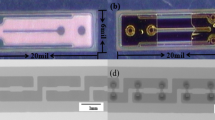

This paper investigates the effect of different soldering temperatures on the performance of the flip-chip light-emitting diode (FC-LED) filament during direct soldering. The changes in the intermetallic compound (IMC) interface, push–pull force and chip fracture surface of the chip solder joints under direct soldering temperatures of 220°C, 260°C, and 320°C for the flip-chip LED filament were explored by scanning electron microscopy (SEM). Thereby, the optimal soldering temperature of direct joining in actual production is compared. The results show that when the soldering temperature is 260°C, Cu on the substrate begins to diffuse into the solder and react with the solder in the lower layer. The Sn content is relatively uniform, and the average push–pull force of the chip increases. The fracture occurs from inside the solder. With a soldering temperature of 260°C, it is observed that the interface shear stress of the flip-chip LED chip is the largest, and the mechanical stress and residual stress are the lowest.

Similar content being viewed by others

References

K.W. Moon, W.J. Boettinger, U.R. Kattner, F.S. Biancaniello, and C.A. Handwerker, J. Electron. Mater. 29, 1122 (2000).

K.S. Kim, S.H. Huh, and K. Suganuma, J. Alloys Compd. 352, 226 (2003).

C.E. Ho, R.Y. Tsai, Y.L. Lin, and C.R. Kao, J. Electron. Mater. 31, 584 (2002).

C.M. Miller, I.E. Anderson, and J.F. Smith, J. Electron. Mater. 23, 595 (1994).

M.G. Cho, S.K. Kang, and S.H.M. Lee, J. Electron. Mater. 36, 1501 (2007).

S.L. Allen, M.R. Notis, R.R. Chromik, R.P. Vinci, D.J. Lewis, and R. Schaefer, J. Mater. Res. 19, 1425 (2004).

V.A. Handara, I. Radchenko, S.K. Tippabhotla, K.R. Narayanan, G. Illya, M. Kunz, N. Tamura, and A.S. Budiman, Sol Energy Mater. Solid C 162, 30 (2017).

T. Tian, R. Morusupalli, H. Shin, H.Y. Son, K.Y. Byun, Y.C. Joo, R. Caramto, L. Smith, Y.L. Shen, and M. Kunz, Proc. Eng. 139, 101 (2016).

A.S. Budiman, H.A.S. Shin, B.J. Kim, S.H. Hwang, H.Y. Son, M.S. Suh, Q.H. Chung, K.Y. Byun, N. Tamura, and M. Kunz, Microelectron. Reliab. 52, 530 (2012).

S.K. Tippabhotla, I. Radchenko, K.N. Rengarajan, G. Illya, V. Handara, M. Kunz, N. Tamura, and A.S. Budiman, Proc. Eng. 139, 123 (2016).

I. Radchenko, S.K. Tippabhotla, N. Tamura, and A.S. Budiman, J. Electron. Mater. 45, 6222 (2016).

I. Radchenko, H.P. Anwarali, S.K. Tippabhotla, and A.S. Budiman, Acta Mater. 156, 125 (2018).

H.P.A. Ali, I. Radchenko, N. Li, and A. Budiman, J. Mater. Res. 34, 1564 (2019).

Giro and A. Violeta, Comprehens. Anal Chem. 75, 153 (2017).

H. Fallahi, M.S. Nurulakmal, A.F. Arezodar, and J. Abdullah, Mater Eng. 553, 22 (2012).

L. Yang, J. Ge, Y. Zhang, J. Dai, and Y. Jing, J Mater Sci. Mater. El. 26, 613 (2015).

R.M. Shalaby, Cryst. Res. Technol. 45, 427 (2010).

M. Yunus, K. Srihari, J.M. Pitarresi, and A. Primavera, Microelectron. Reliab. 43, 2077 (2003).

K. Weinberg, T. Bohme, and W.H. Müller, Comput. Mater. 45, 827 (2009).

D. Kim, J.H. Chang, J. Park, and J. Pak, J Mater Sci. Mater. El. 22, 703 (2011).

C. Ming, C. Lung, and K. Lin, J. Electron. Mater. 32, 1426 (2003).

Z. Huang, P. Kumar, I. Dutta, J.H.L. Pang, and R. Sidhu, Eng. Fract. Mech. 131, 9 (2014).

M. Du, Q. Guo, Z. Ouyang, K. Wei, and W.G. Hurley, Case Stud. Therm. Eng. 14, 100492 (2019).

I.E. Anderson and J.L. Harringa, J. Electron. Mater. 33, 1485 (2004).

I.E. Anderson, B.A. Cook, J. Harringa, and R.L. Terpstra, J. Electron. Mater. 31, 1166 (2002).

T. An and F. Qin, J Electron Packaging. 138, 1224 (2016).

X. Xi, H. Li, F. Wallin, A. Avelin, X. Yang, and Z. Yu, Energy Proc. 54, 2907 (2019).

S.W.M. Ridhuan, S.Kumar Tippabhotla, A.A.O. Tay, and A.S. Budiman, Adv. Eng. Mater. 10, 1002 (2019).

Z. Guo, X. Wang, Y. Liu, Y. Liu, and F. Li, J. Constr. Steel Res. 172, 106174 (2020).

Y. Lei, C. Xiao, X. Wang, J. Yue, and Q. Zhu, Fusion Eng. Des. 95, 27 (2015).

P. Peasura and B. Poopat, Adv. Mater. Res. 214, 108 (2011).

G. Park, S. Uhm, and C. Lee, Mater. Sci. Eng. A 788, 139477 (2020).

J.M. Song, H.Y. Chuang, and Z.M. Wu, J. Electron. Mater. 36, 1516 (2007).

Y. Kariya, T. Hosoi, S. Terashima, and T.M. Otsuka, J. Electron. Mater. 33, 321 (2004).

A. Kroupa, D. Andersson, N. Hoo, J. Pearce, A. Watson, A. Dinsdale, and S. Mucklejohn, J. Mater. Eng. Perform. 21, 629 (2012).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zhai, X., Guan, C., Li, Y. et al. Effect of Different Soldering Temperatures on the Solder Joints of Flip-Chip LED Chips. J. Electron. Mater. 50, 796–807 (2021). https://doi.org/10.1007/s11664-020-08517-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11664-020-08517-9