Abstract

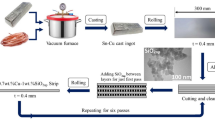

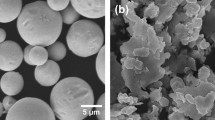

In the present study, new lead-free Sn-Al solders are developed incorporating varying amount of Al (0.4 and 0.6% by weight) into pure Sn using disintegrated melt deposition technique. Solder samples were then subsequently extruded at room temperature and characterized. Microstructural characterization studies revealed equiaxed grain morphology, minimal porosity, reasonably uniform distribution of Al particles and good Sn-Al interfacial integrity. Melting temperature of Sn-0.6Al (228°C) was found to be close to the eutectic Sn-0.7Cu (227°C) solders. Microhardness was increased with increasing amount of Al in pure Sn. Room temperature tensile test results revealed that newly developed Sn-0.6Al solders exhibited significant improvement in 0.2% yield strength (∼67%), ultimate tensile strength (∼18%) and ductility (∼123%) when compared to commercial Sn-0.7Cu solder. Ductility was improved about 222%, 263% and 81% when compared to commercially available Sn-3.5Ag-0.7Cu, Sn-3.5Ag and Sn-37Pb solders, respectively without compromising strength.

Similar content being viewed by others

References

K. Suganuma, Current Opinion in Solid State and Materials Science 5, 55 (2001).

M. E. Alam, S. M. L. Nai, and M. Gupta, J. Alloys Compd. 476, 199 (2009).

M. E. Alam and M. Gupta, Electron. Mater. Lett. 9, 575 (2013).

A. Ku, O. Ogunseitan, J. D. Saphores, A. Shapiro, and J. M. Schoenung, 53 rd Electronic Components and Technology Conference (ECTC), p. 47, New-Orleans, Louisiana, USA (2003).

H. J. Lau and L. D. Jun, Global SMT & Packaging 6, 10 (2006).

P. J. F. Le Fevre, in: Proceedings of IEEE Applied Power Electronics Conference and Exposition, p. 121, IEEE Conference Publications (2002).

O. A. Ogunseitan, JOM 55, 49 (2003).

M. Abtew and G. Selvaduray, Mater. Sci. Eng. R. Reports 27, 95 (2000).

J. L. Freer and Jr. J. W. Morris, J. Electron. Mater. 21, 647 (1992).

M. Hansen and K. Anderko, Constitution of Binary Alloys, p. 55, McGraw-Hill, New York (1958).

F. Hua and J. Glazer, Proc. of 1997 TMS Annual Meeting and Exhibition on Design and Reliability of Lead-Free Solders and Solder Interconnects (eds. R. K. Mahidhara, D. R. Frear, S. M. L. Sastry, K. L. Liaw, and W. L. Winterbottom), p. 65, The Minerals, Metals and Materials Society, Warrendale, PA, USA (1997).

J. Glazer, Int. Mater. Rev. 40, 65 (1995).

Solid State Technology, http://citrix.cleanrooms.com/index/display/semiconductors-article-display/289102/articles/advancedpackaging/industry-news/2007/04/raw-materials-pressuresolder-surcharges.html (2007) Last assessed 20 March 2013.

M. E. Alam, M. Gupta, and A. M. S. Hamouda, Qatar Foundation Annual Research Forum (QFARF), QNCC, Doha, Qatar (2012).

Cost of Lead-Free Solder Materials: A Research Report by the IPC Solder Products Value Council. http://www.adhesivesmag.com. Last assessed 20 March 2013.

Kitco: Base Metals Charts and Graphs, http://www.kitcometals.com/charts/. Last assessed 20 March 2013.

The International Technology Roadmap for Semiconductors, Executive Summery, 2007 ed., http://public.itrs.net/. Last accessed 20 March 2013.

N. TuK, A. M. Gusak, and M. Li, J. App. Phys. 93, 1335 (2003).

R. R. Tummala, Semiconductor International, June (2003).

W. Gibson, S. Choi, T. R. Bieler, and K. N. Subramanian, Proceedings of the 1997 IEEE International Symposium on Electronics and the Environment, p. 246, San Francisco, USA (1997).

K. L. Lin, L. H. Wen, and T. P. Liu, J. Electron. Mater. 27, 97 (1998).

K. L. Lin and T. P. Liu, Oxidation of Metals 50, 255 (1998).

P. Zhang, H. Guo, F. Yang, and J. Xu, Proc: 7 th International Conference, Electronic Packaging Technology, ICEPT ′06, p. 1, Shanghai, China (2006).

K. F. Ho, M. Gupta, and T. S. Srivatsan, Mater. Sci. Eng. A 369, 302 (2004).

R. A. Karnesky, L. Meng, and D. C. Dunand, Acta Mater. 55, 1299 (2007).

S. M. L. Nai, J. Wei, and M. Gupta, J. Electron. Mater. 37, 515 (2008).

K. D. Kim and D. D. L. Chung, J. Electron. Mater. 31, 933 (2002).

F. Guo, J. G. Lee, T. Hogan, and K. N. Subramanian, J. Mater. Res. 20, 364 (2005).

P. E. Gise and R. Blanchard, Semiconductor and integrated circuit fabrication techniques, p. 21, Reston Pub. Co, Res ton, VA (1979).

J. R. Devis, P. Allen, S. R. Lampman, T. B. Zorc, S. D. Henry, J. L. Daquila, A. W. Ronke, J. Jakel, and K. L. O’Keefe, Properties and Selection: Nonferrous Alloys and Special-Purpose Materials, p. 1132, Formarly tenth edition, ASM Handbook, Vol. 2, ASM, Metal Park, Ohio, (1993).

Technical Data Sheet, Qualitek Group of Companies, Qualitek, Singapore, www.qualitek.com. Last assessed 20 September 2012.

D. Lin, G. X. Wang, T. S. Srivatsan, M. Al-Hajri, and M. Petraroli, Mater. Lett. 53, 333 (2002).

J. L. Marshal and J. Calderon, Soldering Surf. Mount Technol. 26, 22 (1997).

H. Baker, Alloy Phase Diagrams, p. 283, Formarly Tenth Edition, ASM Handbook, Vol. 3, ASM, Metal Park, Ohio, (1993).

W. D. Callister, Materials Science and Engineering: An Introduction, p. 175, 620, 6th ed., Wiley, Malaysia (2007).

G. F. Bocchinni, The Int. J. Powder Metallurgy 22, 185 (1986).

B. D. Cullity, Elements of X-ray Diffraction, 3rd ed., Prentice Hall, London (2001).

S. F. Hassan, K. F. Ho, and M. Gupta, Mater. Lett. 58, 2143 (2004).

G. E. Dieter, Mechanical Metallurgy, p. 191, 2nd Edition, McGraw-Hill, Inc., USA (1976).

S. M. L. Sastry, D. R. Frear, G. Kuo, and K. L. Jerina, Proc. Mechanics of Solder Wetting and Spreading (eds. F. G. Yost, F. M. Hosking, and D. R. Frear), p. 299, Van Nostrand, New York (1993).

D. C. Lin, S. Liu, T. M. Guo, G. X. Wang, T. S. Srivatsan, and M. Petraroli, Mater. Sci. Eng. A 360, 285 (2003).

B. Jing, S. Yangshan, X. Feng, X. Shan, Q. Jing, and T. Weijian, Scripta Mater. 55, 1163 (2006).

M. Kouzeli and A. Mortensen, Acta Mater. 50, 39 (2002).

S. F. Hassan and M. Gupta, Mater. Sci. Eng. A 425, 22 (2006).

X. L. Zhong and M. Gupta, J. Phys. D —Appl. Phys. 41, 095403 (2008).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Alam, M.E., Gupta, M. Development of extremely ductile lead-free Sn-Al solders for futuristic electronic packaging applications. Electron. Mater. Lett. 10, 515–524 (2014). https://doi.org/10.1007/s13391-013-3087-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13391-013-3087-1